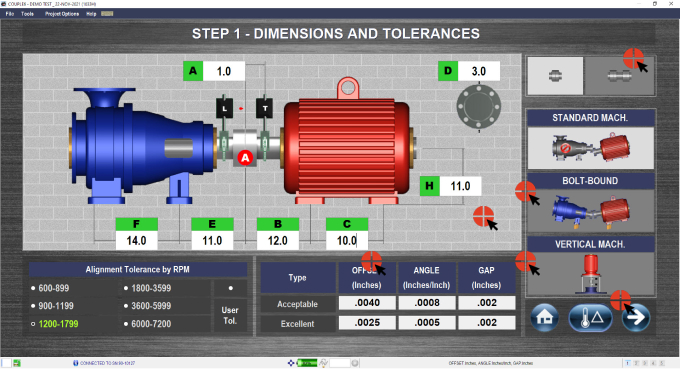

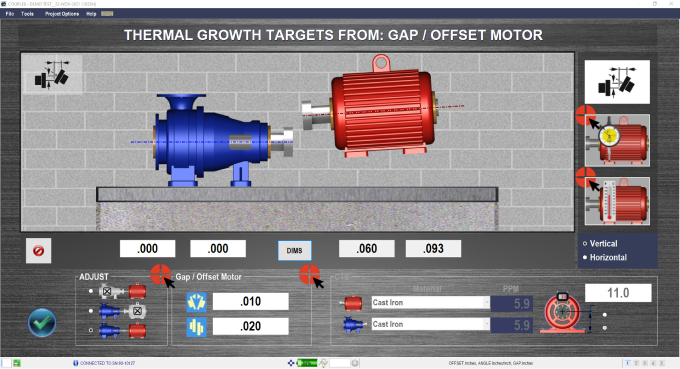

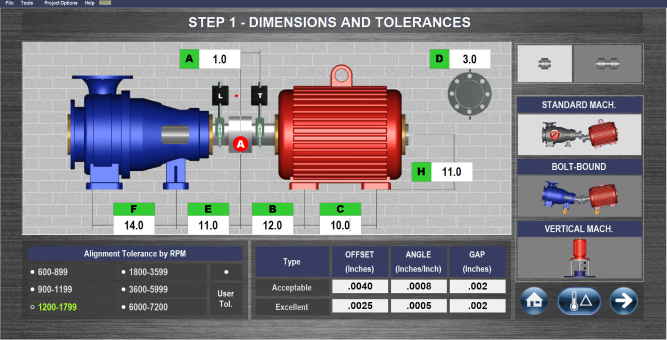

Thermal growth offsets (the amount the motor grows from a cold start to operating temperature) are also entered at this stage by clicking on the Thermal Growth icon  and opening the modeling screen.

and opening the modeling screen.

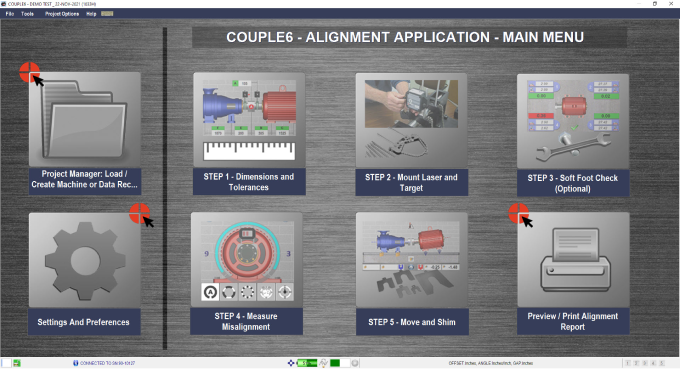

Navigate between the 5 main alignment steps, manage project files, print reports and change alignment settings.

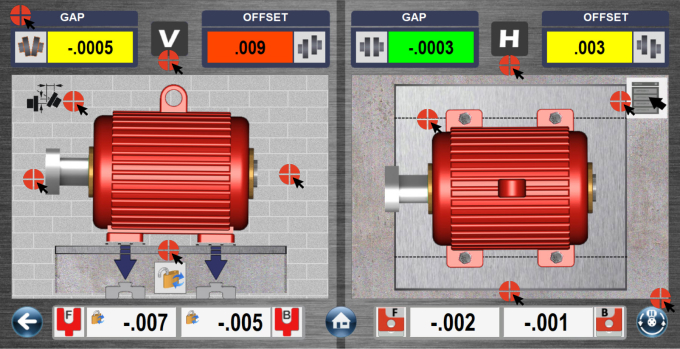

Enter thermal growth offsets in Coupling Mode or Foot Mode and go back to Dimension Screen and Couple6 will automatically apply these offsets to the alignment in Step 5. So after aligning the machine, with these offsets applied, the motor will be “misaligned” by the offset value. This means when the motor (or pump) gets up to operating temperature, it will “grow” into alignment.

Values can be entered either at the feet or the coupling. There is also a foot calculator where you can enter the foot temperatures and the material type and Couple6 will calculate how much the feet will grow and how much this will affect the alignment at the coupling and the feet.

All thermal growth offsets can be applied to the horizontal axis too!

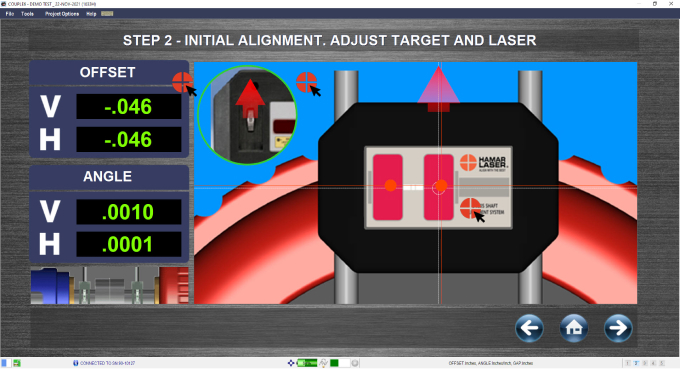

With our X-880/X-990, the Step 2 Laser Setup Screen provides a live display in all 4 alignment axes (2 measurement planes) to adjust the laser or target to maximize the measurement range of the target. However, the system can still be used even if the laser beams are not aligned.

With on-screen instructions, the user is directed to adjust the laser to bring the readings within +/- .040″ (1 mm) of zero. Adjustments to the Vertical Offset are made by moving the laser up or down on the brackets. Adjustments to the Horizontal Offset are made by turning a wheel on the front of the laser. Couple6 automatically tells you which direction to adjust the wheel to bring the offset values into alignment

No More Rough-In Alignment!

Normally, with the large measuring range of the X-Series™ , it is not needed but in cases where large motors are installed, this screen can be used to “rough in” the motor’s angular misalignment so the laser can take data for the final alignment. For the vertical axis, simply rotate the laser from 12:00 to 6:00 and average the 2 angular readings, which gives you the rough angular misalignment in inches/inch or mm/100 mm. Multiply this by the C dimension from Step 1 and add or subtract the result from the front or back feet to align the angle of the motor. Repeat this for the Horizontal axis by rotating the laser from 3:00 to 9:00.

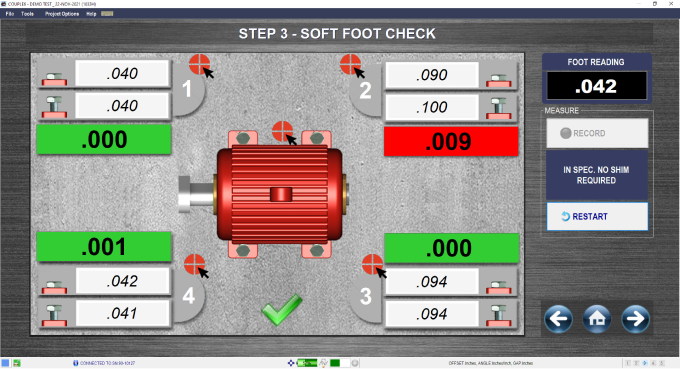

To use the Soft Foot Screen, simply hit Record with the bolt tight. Then loosen it and take a second reading. Couple6 will then record the difference. Repeat this for all 4 feet and Couple6 will find the foot with the biggest difference and if it is greater than the tolerance, it will recommend the shim to add to fix it.

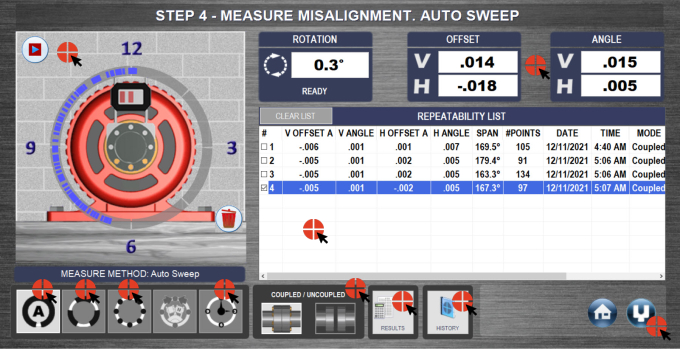

Once the data is taken, Couple6 pops up a window showing the data and if accepted, it will then be put into the Repeatability Table for comparison to previous sets of data. Then highlight a set of data and click the Results button to see the results with tolerances applied. Multiple sets of data can also be averaged and used for the alignment if repeatability is a problem. Data can also be added to History for archiving purposes.

The angular values can be displayed as angles or gap with a click of the button. And our uniqueFlip-It™feature allows you to flip the motor if you find yourself on the wrong side. The data-updating speed (averaging) can also be adjusted to smooth out fluctuations in the readings due to air turbulence or vibration.