We know how to make alignment lasers. We’ve been doing it for nearly 54-years, and shaft alignment for 26 years. So when we decided to redesign our shaft alignment systems, we worked on everything, from the electronics to the brackets to the software, to bring you the best, most accurate, easy-to-use series of laser alignment systems on the market today. And we made the entire series wireless because we all know how much of a pain wires can be, not to mention potentially dangerous, too.

We also worked very hard on our software to make it so easy to use that training is only needed for the more complicated applications. One of our distributors told us that his users can put the system away for a month and take it out of the box and start using it without having to pull out a manual. Talk about easy!

A patented technology that allows the measurement of offset and angle simultaneously with only one PSD, increasing system accuracy by 50%. We also perform up to a 500-point calibration on the PSD to provide the industry’s highest accuracy that is up to 15-times more accurate than our competitors systems. Dual-Beam technology also provides an amazing +/- 12 degrees of angular range to ensure the laser stays on the target during data taking on long-distance applications and an angular resolution that is 10 times higher than the highest angular tolerance. Finally, blinking laser technology provides ambient light compensation.

We designed our Dual-Fan™ technology to be economical, versatile and accurate for our entry-level shaft alignment system. Dual-Fan™ technology allows highly accurate measurement of offset and angularity simultaneously, using two 0.5-degree laser fans and two 20 mm PSDs. We also designed a special laser fan that only fans out to 1 inch (25.4 mm) at 15 feet (4.6 m), making it much safer than competitors lasers that can fan out to 1.5 feet (0.5 m), which we think is a safety issue.

Dual-Fan™ also provides full angular measuring range over the entire operating range between laser and target, unlike the “cross-fire” lasers (2-laser, 2-detector systems) that have severely restricted angular measuring range when the distance between laser and target is greater than 3 feet (1 m).

And to make the Dual-Fan™ technology up to 5 times more accurate than competing mid-priced systems, we perform a 40-point calibration procedure on the PSD. Blinking laser-fan technology also provides ambient light compensation.

All X-Series™ alignment hardware “heads” are compact, rugged and built to quickly and easily provide clear, dependable, accurate alignment data. They feature an environmental rating of IP67 for waterproof protection (can be dunked in a bucket of water up to 3 feet or 1 meter) and rugged handheld display units that feature high-resolution, color touchscreens. In addition, unlike some of our competitors, our wireless transmitter is safely sealed inside our heads, so there are no connectors or cables that can fail or wear out.

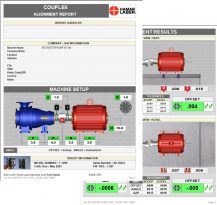

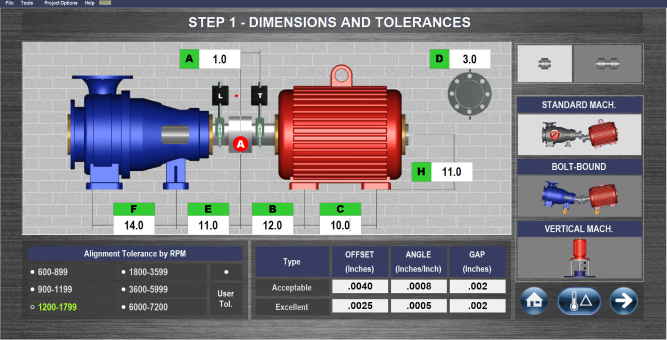

Our Couple6 software is every bit as brilliant as our hardware, featuring our Easy-Guide™ navigation with its easy-to-follow, high-quality color screens that makes even the novice user look like an expert! Just follow our 5-step process that guides you through each stage of the alignment and before you know it, you’ll be printing a report!

For our 3-axis systems, the X-660 and X-770, we offer our intuitive simultaneous 2-axis “live” display with continuously updating graphics to illustrate the motors’ alignment in either horizontal or vertical axis (plane) of the alignment. To see the horizontal axis live move screen, just rotate the shafts from 12:00 to 3:00 or 9:00 and Couple6 will automatically switch the Step5 Move Screen to the Horizontal Axis to display the alignment results so you can begin moving the motor, all without having to retake data!

Our extra-large 20-33 mm PSD measuring areas in our target heads and our +/- 8 to +/-12 degrees of angular range combined with our uni-directional laser beams mean you can skip the ever time-consuming “rough” (pre) alignment of the motor during new machine installations. This saves tons of hours of labor each month! Just clamp the laser and target on the shafts and go to our Step 2 Laser Setup Screen where there is a live display of the rough angular alignment. Then rotate the shafts and if you get numbers for at least 90 degrees, you can go to take data! If not, you can use the live display to roughly align the motor in angle so you can take data. It is that simple!

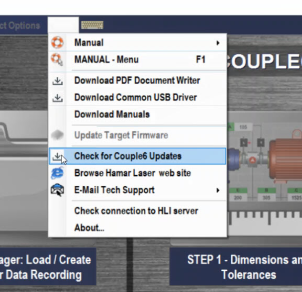

If you forget how to do something, then you can quickly access our manual right in our Couple6 software by selecting the Help Menu (or hitting F1) and the correct page of the manual will automatically display. Or, launch one of the training videos for a quick recap of a procedure. Compare that to our competitors’ multi-page cheat sheets or 100+-page manuals that you can read while you are at the office or print out to bring with you on the job! With software this easy to use, training is really only required for the more complicated applications.

Even if you purchase one of our entry-level laser systems, you can easily upgrade it to have more advanced features. Just email us or your distributor a purchase order for the new features and within a day or so you will get a new license by email that installs on your tablet in seconds! Then just open up our Couple6 software and the new feature will be there!