Why Laser Alignment?

ALIGNMENT LASERS. SIMPLY THE BEST

Taking the time to accurately align your machines will reduce costs and increase reliability.

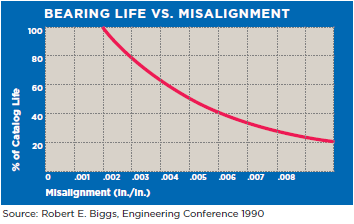

Misalignment costs you serious money-

Misalignment increases bearing and seal where and leads to premature failures. It also increases power consumption of the motor, increasing electrical costs. For example, studies show that for 3000 RPM motor, an increase in the coupling gap of just .015” can cause motor power consumption to rise by 4%. Multiply this by hundreds of machines and this adds up to serious loss of revenue each year.

Increasing alignment accuracy has been shown to:

- Reduce maintenance cost by up to 7%*

- Increase bearing and seal life by up to 8 times*

- Increase machine availability by up to 12%*

- Reduce energy costs by 5% to 12%

- Significantly increase coupling life

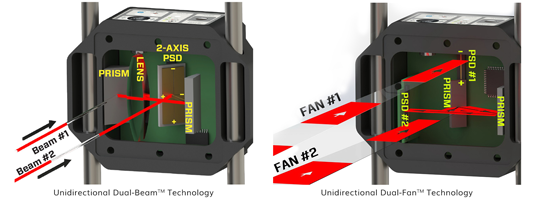

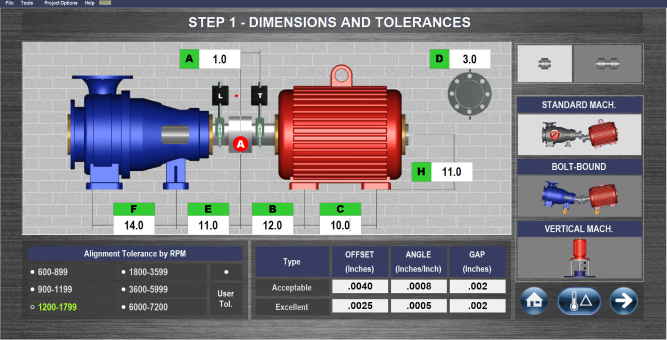

Why lasers are better – After years of successful use, it is now an established fact that lasers are simply the best tool for performing the most accurate shaft, pump and motor alignments in the shortest time possible. The X Series™ lasers offer the following advantages over indicator – based methods:

- Up to 20 times higher measurement resolution.

- 60–70% faster alignments than indicator-based methods.

- Automatic calculation of alignment results, shim and move values without having to use graph paper and calculators!

- With our Easy-Guide™ program flow, easy-to-follow screens to guide you through the alignment, saving on training time and costs

- Automatic data taking with hundreds of data points versus a max of four points with indicators, increasing accuracy and speeding up alignments

- Live move data to help you align your motors quicker, eliminating guesswork

- Eliminates indicator bracket sag

- Printed color alignment reports

*Source: Reliability Centered Maintenance Guide for Facilities and Collateral equipment – NASA.