Part of the X-Series™ Laser Shaft Alignment systems, the most advanced and precise laser alignments systems on the market.

The X-660/X-770 shaft aligners offer these high-tech features:

The X-660/X-770 shaft alignment lasers offer a high-tech laser shaft alignment solution for a very affordable price. Here is a summary:

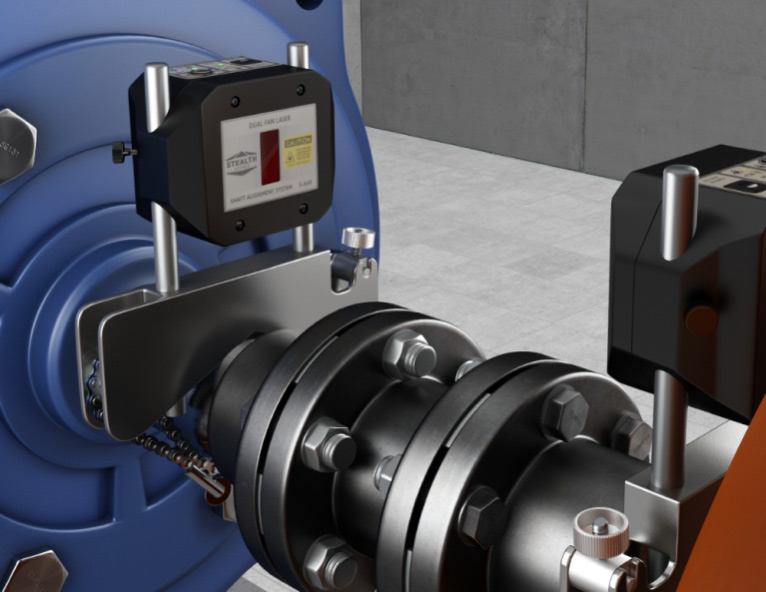

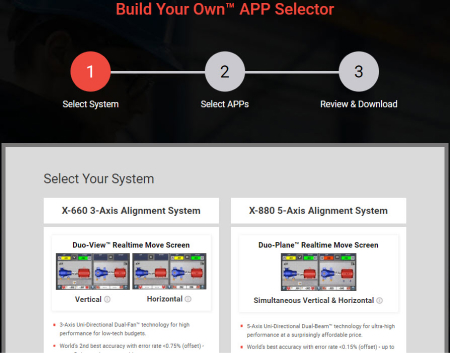

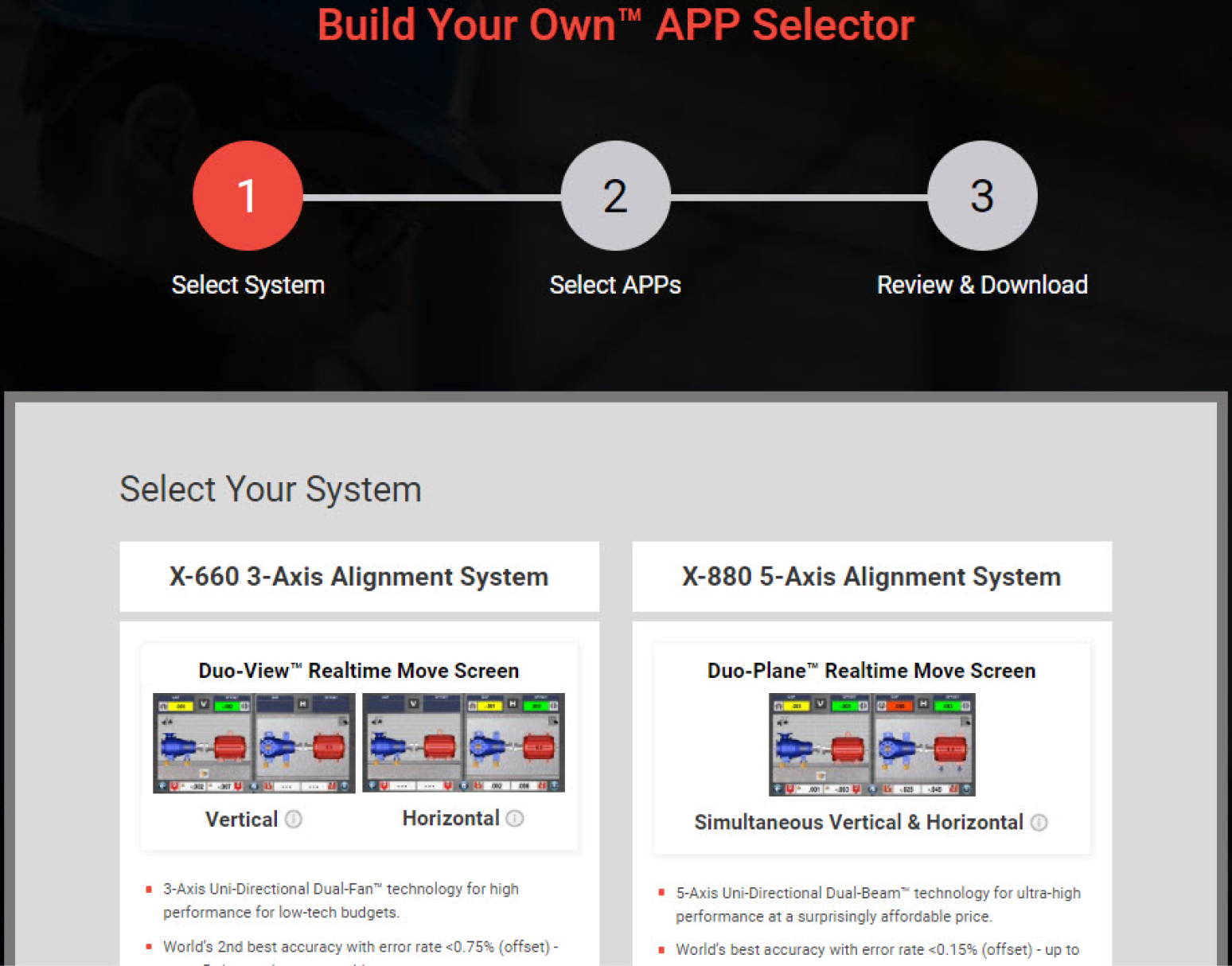

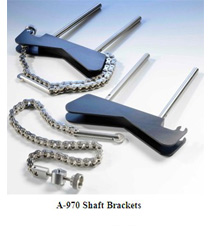

X-660 – A complete shaft alignment laser featuring the advanced L-780 Dual-Fan Laser, T-1280 3-Axis Target, A-970 shaft v-brackets, rugged 10” tablet, and heavy-duty shipping case. It features a Build Your Own (BYO) app selector where you can choose your own apps based upon your individual needs.

X-770 – Offers the same hardware as the X-660 but with a Loaded App software license with most of the optional features thrown in for a discounted price.

For over 50 years, we have been providing highly accurate alignment systems to many different industries and applications. We started in the machine tool industry where tolerances are high and applications are difficult, and then 30 years ago we developed the world’s first 4-axis shaft alignment system. All of that experience and knowledge has gone into the design of the X-660 Wireless 3-axis Shaft Alignment System, resulting in the most accurate and yet easy-to use tool in its class.

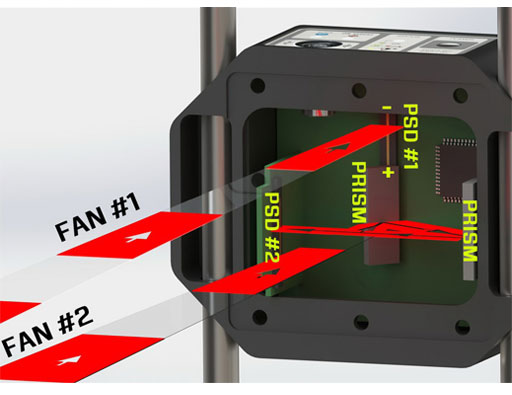

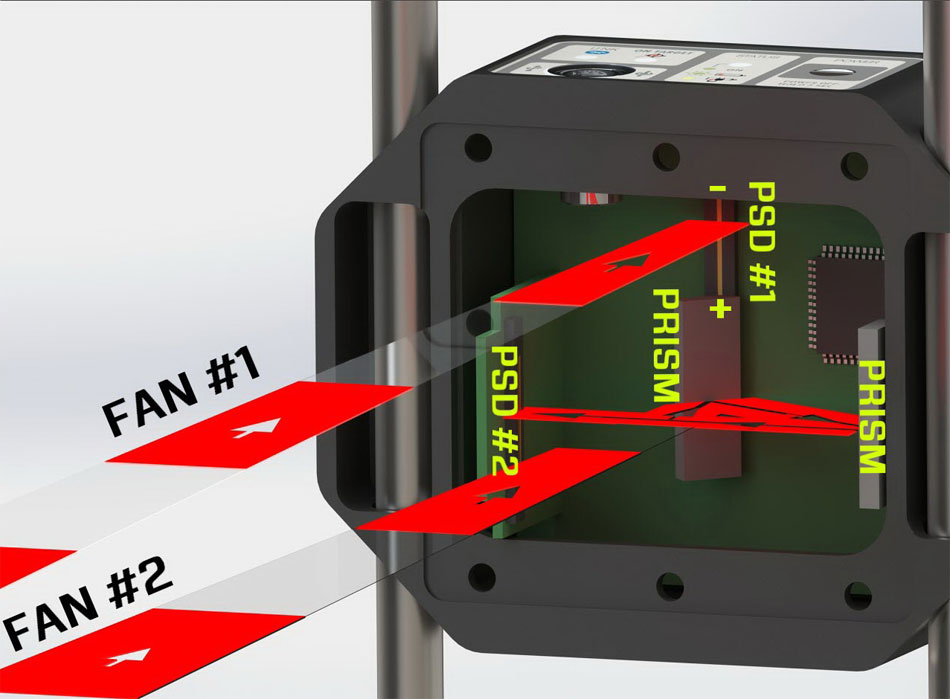

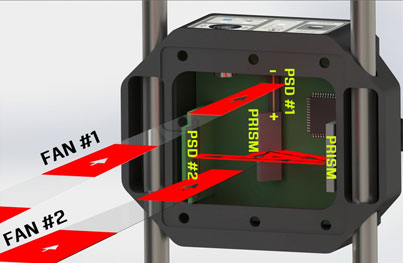

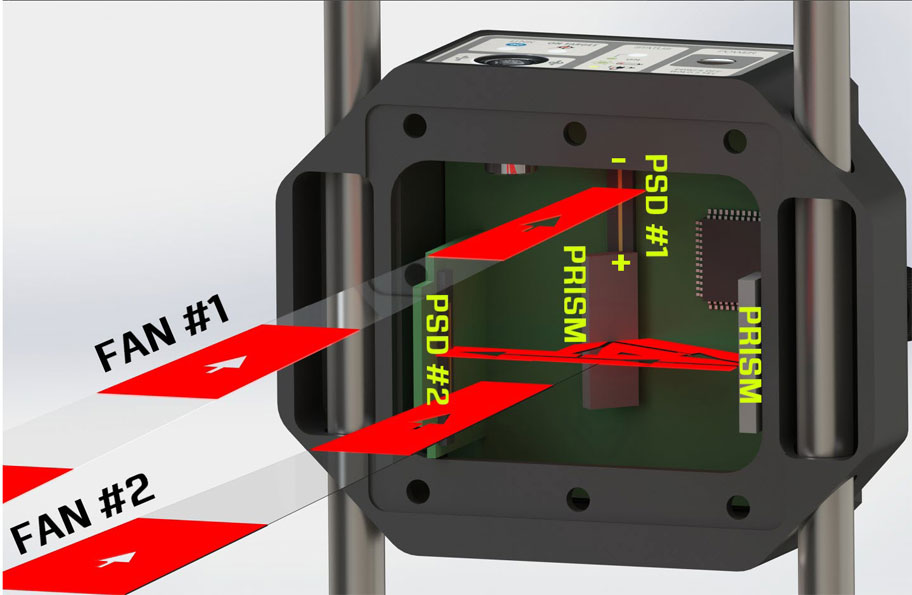

This innovative technology provides an amazing ± 8º of angular range. Utilizing 2 unidirectional laser fans (2 laser fans, 1 direction), it solves the rough-in (pre alignment) problem with “cross-fire” lasers (2 lasers, 2 directions) and makes aligning machines amazingly fast and easy, especially on long-distance applications. The result? More jobs done in less time and happier managers!

All “cross-fire” laser alignment systems require a rough-in (pre-alignment) of the machine before the system be able to take data. With Dual-Fan™ technology’s 2 unidirectional laser fans and 20 mm sensors, you don’t need to rough-in the motor to get it to take data. You get the same measuring range from 2 in. to 15 ft. (50 mm to 4.5 m), unlike the “cross-fire” kits that have virtually no measuring range beyond 5 ft. (1.5 m). So just slap on the brackets, laser and target and get to work!

With “cross-fire” laser technology, the angular resolution varies with distance. Ironically, it’s the close coupled applications that cause the most problems for angular accuracy for these systems. With our Dual-Fan™ technology, you get the same high angular resolution at 2 in. (50 mm) between heads as you get at 15 ft. (4.5 m), and our angular resolution is 4x higher than the highest angular spec.

Utilizing the power of Windows, our tech support department can log on remotely to the tablet, via WiFi and the Internet, and troubleshoot many problems. We can usually resolve most issues with an online session, keeping you productive and potentially saving a lot of money on costly returns for repairs.

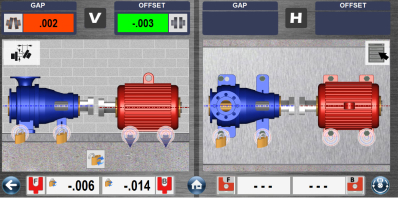

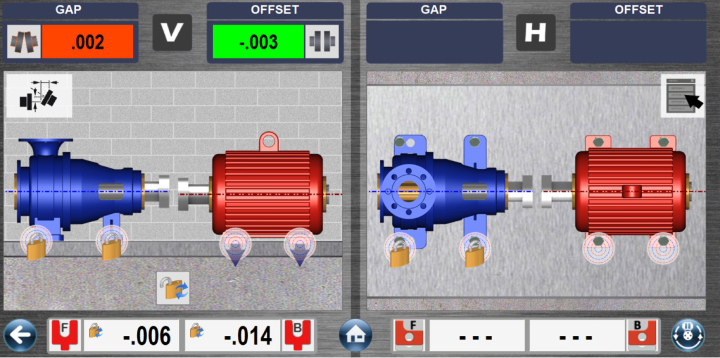

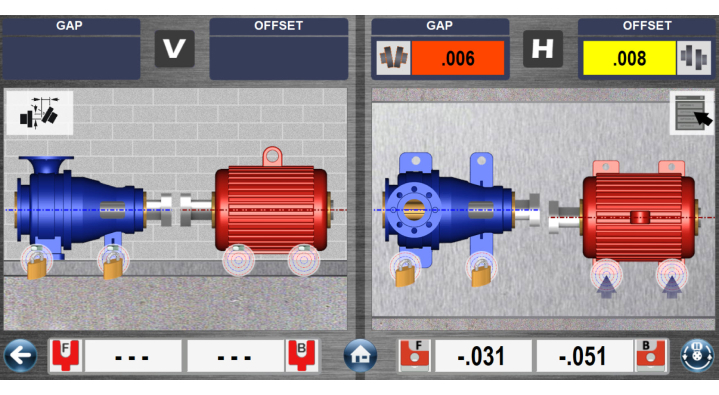

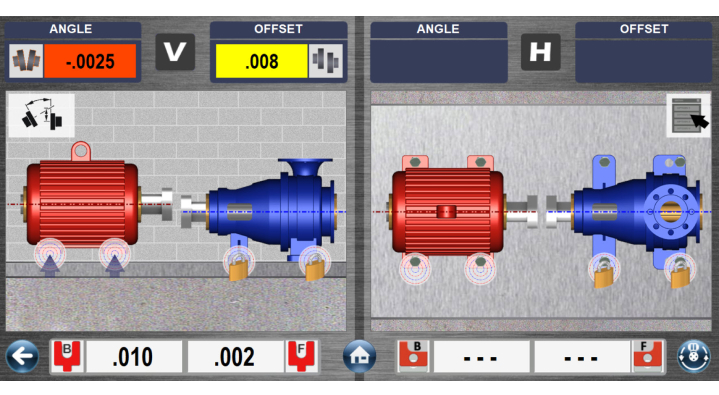

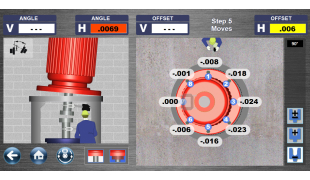

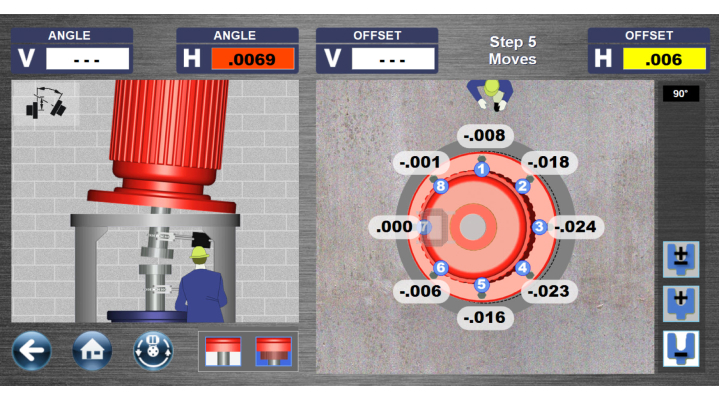

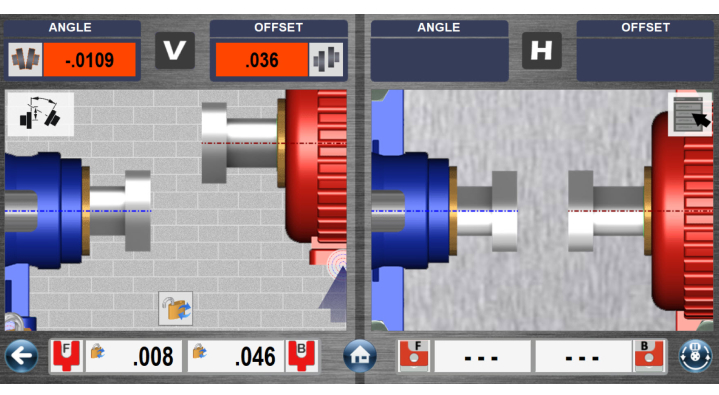

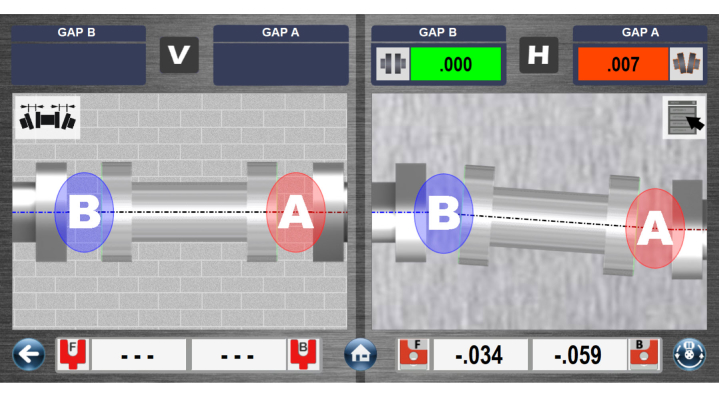

Our Duo-View™ realtime move screen and 3-axis target allow you to view a live alignment screen for both alignment planes (4 axes) on the same screen. To switch views, just rotate the shafts to a clock position and the view is automatically switched, and the non-live axis is grayed out so there is no confusion!

High-resolution PSD technology and 60-point sensor linearization reduce the target error rate to <0.75%, which is up to 5x higher than our competitors’ entry-level lasers and gives you the confidence that when the displays turn green, the motor is aligned as accurately as possible. Higher accuracy also means better repeatability and more accurate shim calculations so you don’t have to keep doing the alignment over and over again. Shim Once, Move Once™!

Pick only the apps you want with your X-660, using our Build Your Own™ app selector to customize your apps to meet your individual needs. We recommend a set of apps and you can check on/off the app and the price estimate and license are updated to reflect your choices!

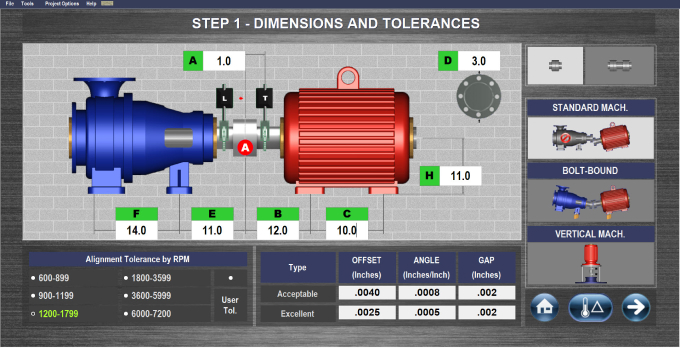

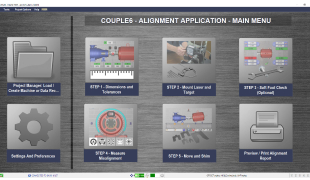

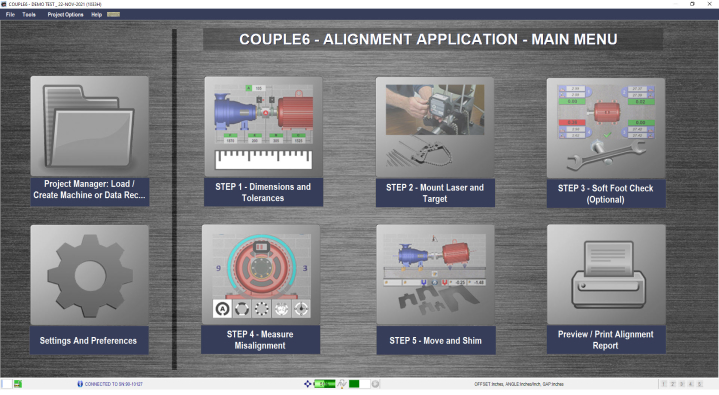

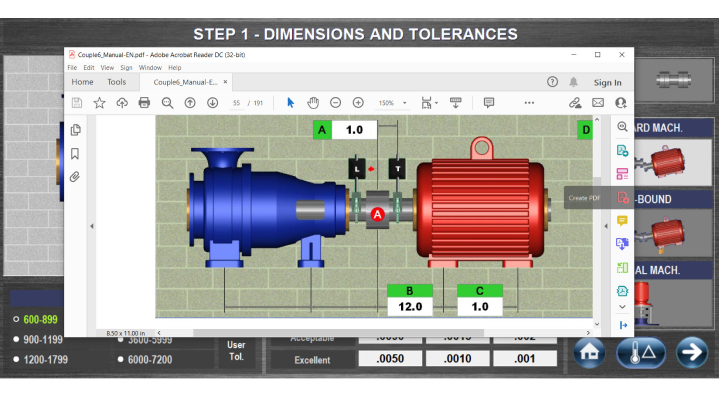

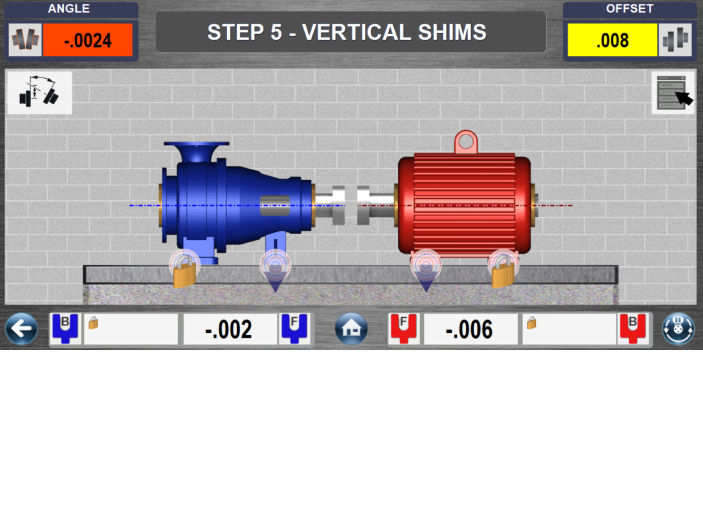

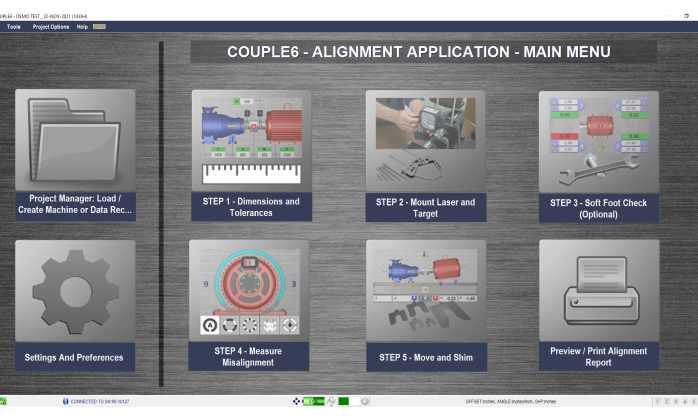

Our Couple6 software features our Easy-Guide™ navigation with its easy-to-follow, high quality screens, leading users through each stage of the alignment. And if you forget how to do something, the manual and training videos are built right into the software! With software this easy to use, a lot of customers start using the X-660 kit right out of the box!

With no hidden warranty fees like other systems, our 5 Year Unconditional Warranty is really that: no conditions! As long as you don’t damage it by abuse, then if something goes wrong, we replace or fix it. That’s it. We also don’t charge any software maintenance fees. Software updates are free for the life of the product!

Some other systems require up to a 20 minute target-lens setup before they take data. With the X-880/X-990 (use X-660/X-770 for the other page), the bracket posts are pre-aligned to the brackets, so you just attach, the brackets, slide on the laser/target and adjust so the laser goes in the window and in 2-3 minutes, you’re ready to take data!

We designed the Couple6 PC software with the novice user in mind and created our Easy Guide™ approach to navigation that is so simple to use, it requires little to no training. Easy-to-follow, high quality, screens lead you through each stage of the alignment, so you don’t need to constantly refer to “cheat sheets” just to remember how to use it!

Couple6 software is a powerful shaft alignment program designed to run on any Win7/8/10 tablet or laptop PC that has a Bluetooth™ connection. Since Couple6 runs on Windows 10” tablets, you can utilize the power of the tablet to email reports from the field, run other reliability software and many other Windows based programs. This also makes it easy to find a replacement if something happens to the tablet.

Easy-to-follow screens guide you through the alignment, making Couple6 easy enough to use right out of the box with little to no training required!

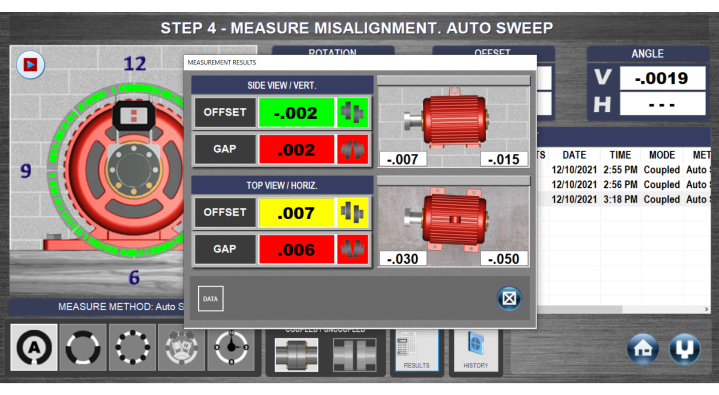

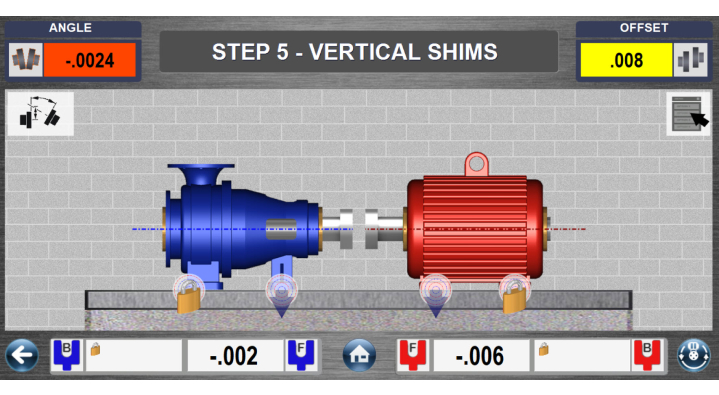

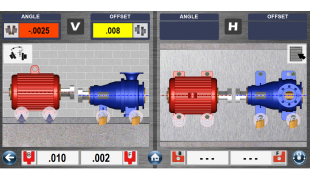

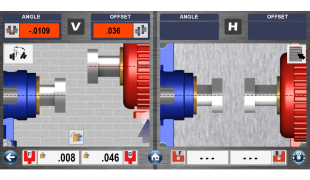

Alignment values update as you adjust the motor in real time. To switch views, rotate the shafts to a clock position and the view switches without any buttons to push. The non-live axis is grayed out to avoid confusion!

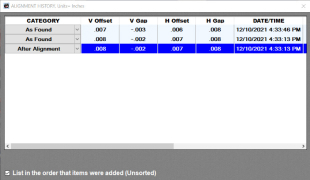

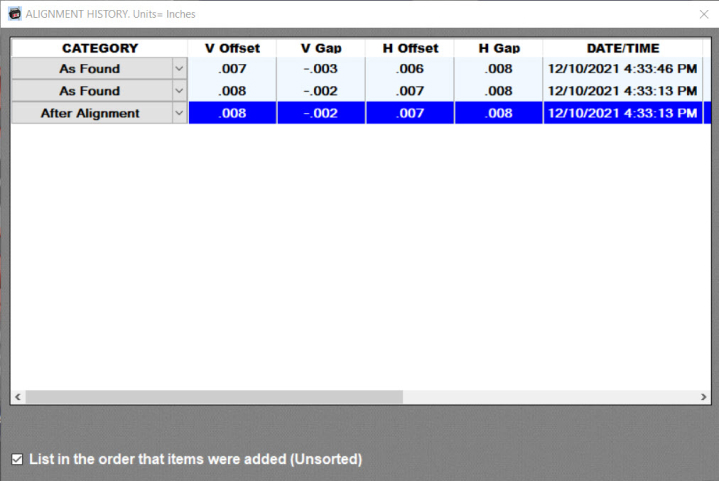

Click on a set of alignment data to display color-code alignment results. Red means Out of Tolerance, yellow means Good and green indicates Excellent. Foot values are also displayed.

Our manual is built right into Couple6 software and is indexed to the currently viewed page. We also uploaded our training videos onto the tablet.

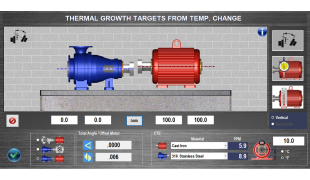

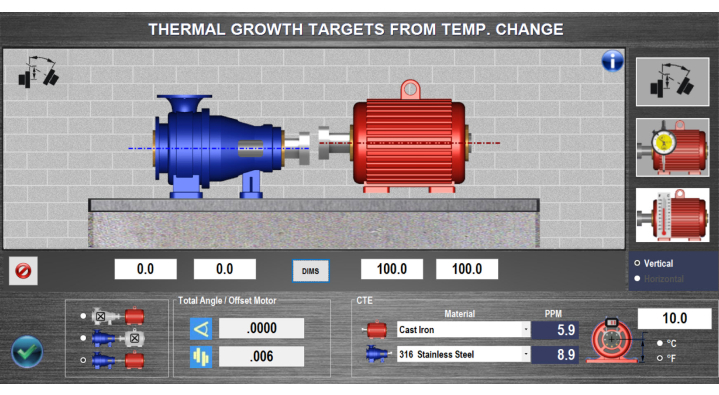

Enter thermal growth values at the coupling or the feet to offset the alignment, and the motor graphics will update to show the effects. Or enter temp changes at the feet, select the material and calculate the alignment effect at the coupling. Great for “what-if modeling”!

Enter dimension of the pump, and then lock different combinations of the motor and pump feet to see how it affects the alignment. The graphics and shim values automatically update with each click.

Couple6 allows the user to flip the motor graphics to match the pump/motor orientation without having to turn the display upside down!

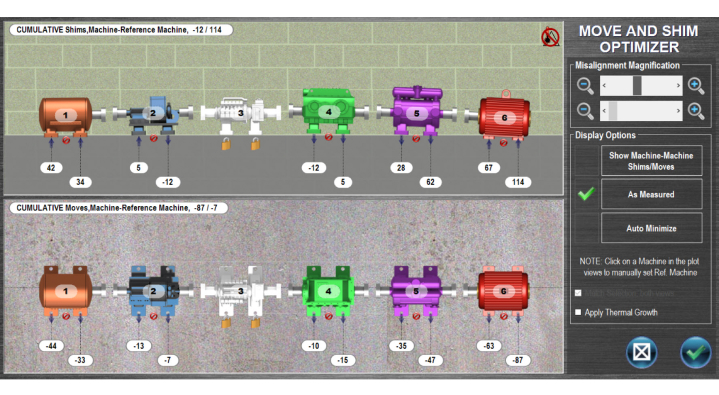

Take data on up to 10 machines and the Train Module will calculate the shims/moves that minimizes the moves. Click on any machine to update the shim/moves of other components.

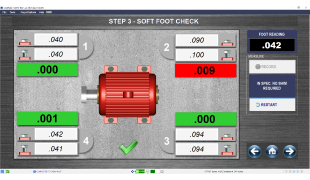

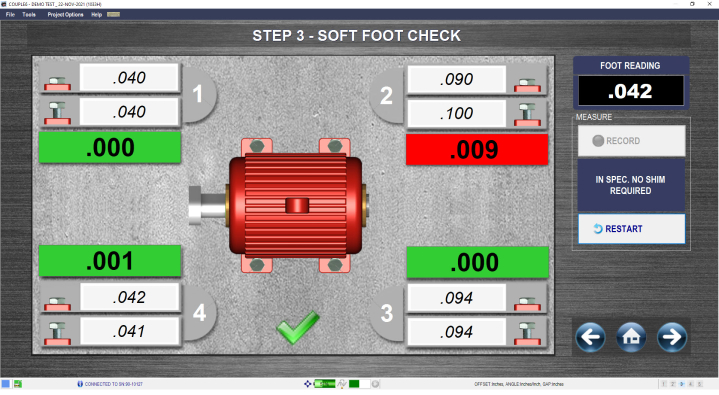

On-screen, easy-to-follow procedure for checking Soft Foot. Automatically selects the “problem” foot and calculates the shim to fix it.

The industry’s only vertical alignment display with live graphical displays of the motor’s alignment along with shim values for all bolt-hole locations.

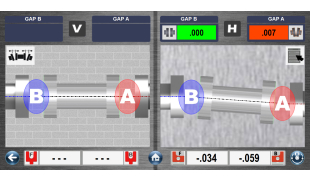

For those more accustomed to gap/offset methods, we added a view right at the coupling to help aid interpreting the results.

For saving data for multiple alignments and keeping track of data trends. Easy dropdown list to catagorize the data.You can even average sets of data together before going to the Move Screen.

Spacer (jack) shaft alignments have different data formats. We offer 7 data formats to match up with OEM alignment specs.

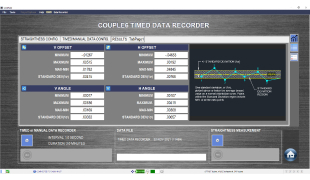

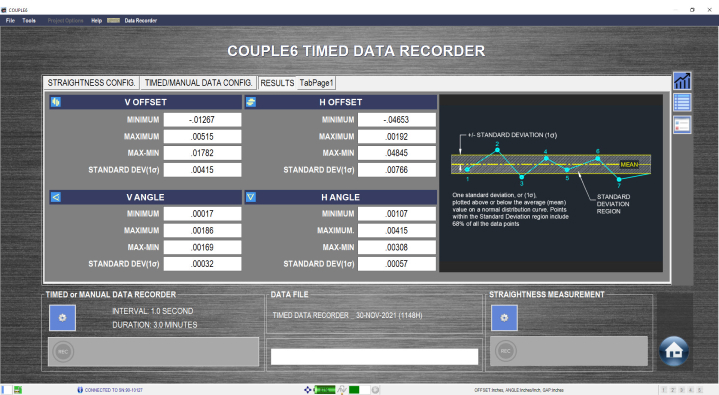

For recording shaft runout or thermal growth. Has a single-point recording mode or a time recording mode. Data is saved in an Excel format for easy uploading and analysis. A report shows min/max, a graph and a table of data.

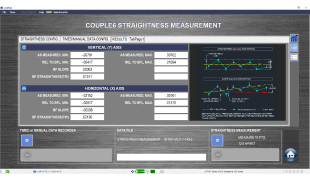

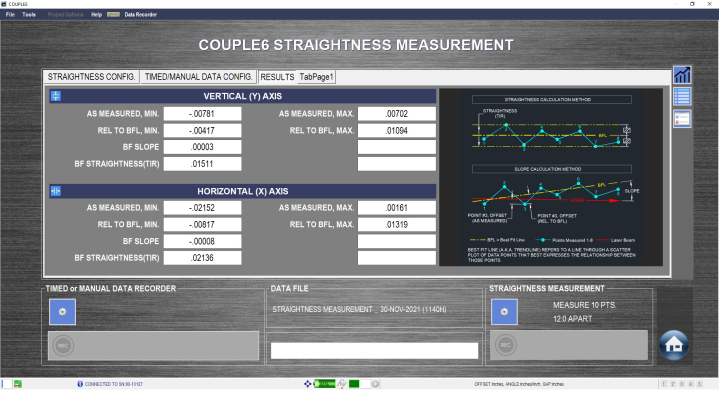

Using our A-987 Base, you can use our shaft alignment lasers to check the vertical/horizontal straightness of rails and surfaces. Couple6 calculates the Best Fit line for the data to provide the overall straightness values. A report shows the straightness TIR, a graph and a table of data.

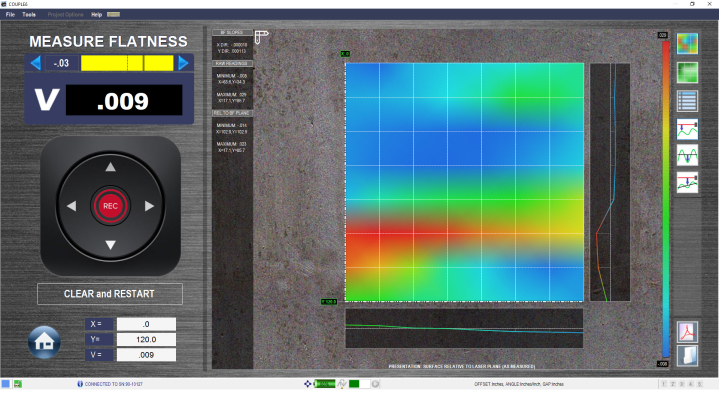

Using our A-987 Base or our more accurate L-730/L-750 Leveling Lasers with our A-1519-2.4ZB Target to measure the flatness of sole plates and other surfaces. Couple6 calculates the Best Fit plane for the data to provide the overall flatness values. A report shows the flatness TIR, a graph and a table of data.

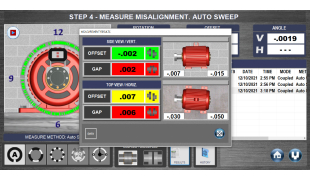

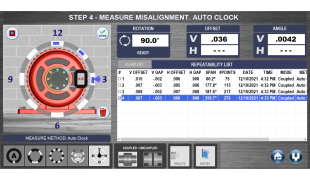

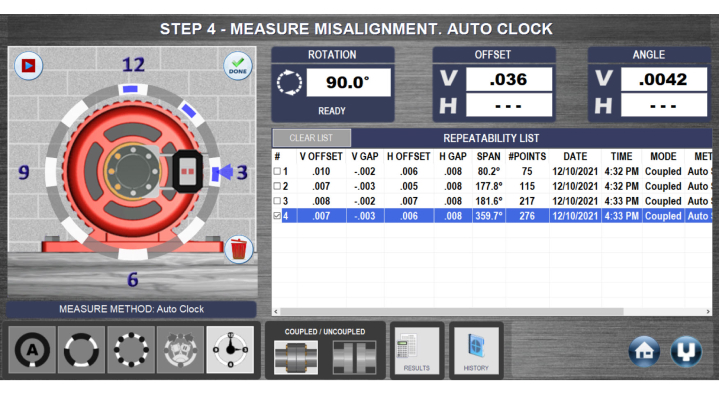

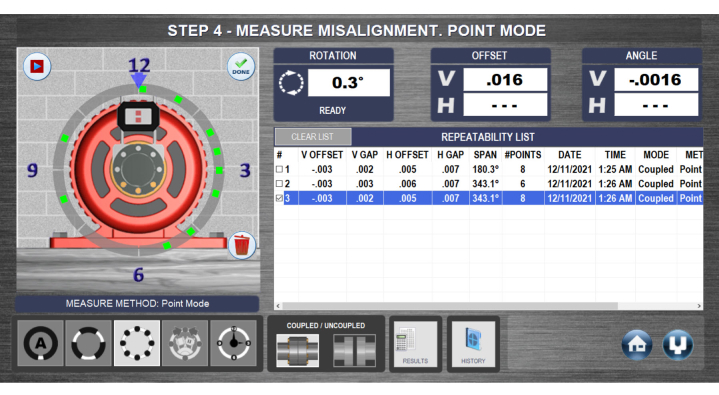

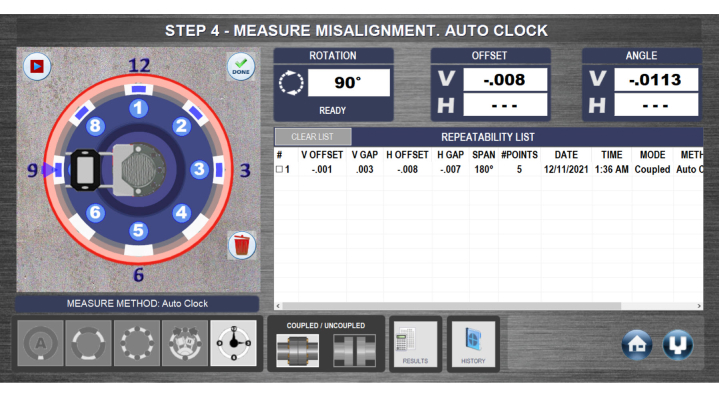

A standard feature, making coupled alignment amazingly easy. The target detects shaft rotation and automatically selects the clock location to record up to 8 data points. More data points mean better accuracy and quicker alignments!

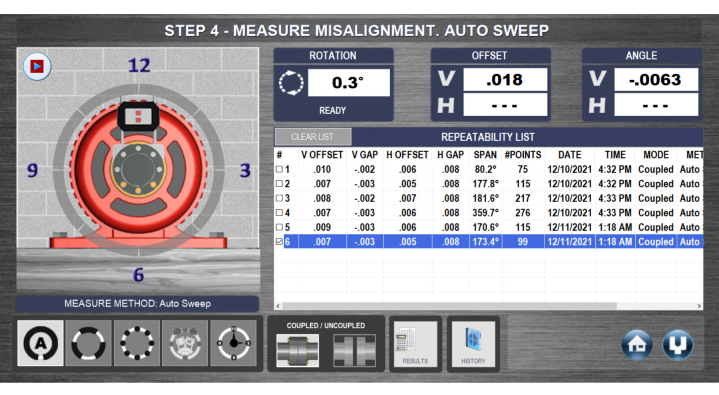

Start rotating the shafts and the accelerometer detects the movement and automatically starts collecting data at 16 readings/sec. Stop rotating the shafts and Couple6 calculates the misalignment. More data means more accurate alignment data and less rework!

Rotate the shafts to any clock location and press Record to take a data point. Collect as few as 3 points and up to 100+ to generate alignment results. Very useful for noisy environments.

Customized graphics make taking data very easy for vertical motors. Just click on a clock location and rotate the laser/target to that point and hit record. Customized vertical move screen graphics make the alignment part a lot easier too!

The X-660/X-770systems use familiar IP65 rugged tablets PCs that are easy to replace. You can even use your laptop if someone runs over your tablet. So there are no expensive, proprietary display devices to replace if broken.

Hamar Laser was the first in industry to offer a rugged tablet PC display box. Why? Instead of offering a high-cost, proprietary display devices like other manufacturers, we wanted our customers to benefit from advances in tablet technology, such as larger screens, megapixel cameras, email on the run, 1 m drop testing, hot swappable batteries, training videos on-demand, nearly unlimited data storage, etc.

Our manual is built right into Couple6 software and is indexed to the currently viewed page. We also uploaded our training videos onto the tablet, so if you need a refresher, you can just click on the video on the desktop and watch away!

Utilizing the power of Windows, our tech support department can log on remotely to the tablet and troubleshoot any problem. All you need is an internet connection.Our support experts can usually resolve most issues with an online session, keeping you productive with the least disruption, potentially saving a lot of money on costly returns for repairs.

Our PC based tablet support many other PC-based condition monitoring (CM) products, allowing you to save money on standalone display boxes for some of the CM products.

R-1342T3-301XI - A high-performance, rugged tablet with a 10.1 in. (254 mm) display, excellent environmental ratings, 8GB of RAM, an upgraded i5-8250U, Quad-Core, ~3.4 GHz processor and 60% higher battery life and faster graphics updating. It also features a camera for taking photos of the setup.

Rugged Tablet Features:

This innovative technology utilizes 2 unidirectional laser fans (2 laser fans shooting in 1 direction) that solves the rough-in (pre-alignment) problem with “cross-fire” lasers (2 lasers, 2 directions) and makes aligning machines amazingly fast and easy, especially on long-distance applications. It also provides a very generous ± 8º of angular range plus a fixed angular resolution that is 4x higher than the highest angular tolerance. The result? More jobs done in less time and happier managers!

One of the laser industry’s highest-resolution single-axis PSD sensor, providing .00004 in. (0.001 mm) resolution and a measuring area of 20x1 mm, among the best in its class.

Our laser fans are very thin (<2 mm), which increases the measurement range of the PSD to handle larger alignment errors. They also have very little divergence, with a max width of 3 in. (76 mm) at 15 ft. (4.5 m), which improves laser safety.

With “cross-fire” laser technology, the angular resolution varies with distance. Ironically it’s the close coupled applications that cause the most problems for angular accuracy for these systems. With our Dual-Fan™ technology, you get the same high, fixed, angular resolution at 2 in. (50 mm) between heads as you get at 15 ft. (4.5 m), and our angular resolution is 4x higher than the highest angular spec.

Dual-Fan™ technology also utilizes blinking laser fans to eliminate the effects of background light. Advanced light filters are also available for direct sunlight apps.

With no cables to trip on or wrap around shafts, the X-770 platform makes for a safer work area, while giving you the freedom to go wherever you need to be, for 15 hours before recharging the battery. Our standard, Class 2 Bluetooth wireless technology offers up to 33 feet of communication range, and for wet work sites. The IP67-rated T-1280 target can be dunked in water up to 3 feet (1m) and still transmit data! Also, our charging cable can be used for communications in case something happens to the wireless.

A waterproof, rugged shipping case with precut foam for all the components of the kit. It holds extras like the: A-982 Magnet Brackets, A-980OF Offset Brackets and several other optional brackets.

| X-660 3-Axis | X-770 3-Axis | ||

|---|---|---|---|

| L-780 Dual-Fan™ Laser Head |

X

|

|

|

| T-1280 Wireless 3-Axis Target |

X

|

|

|

| A-970 Aluminum Shaft Brackets |

X

|

|

|

| R-1342T3-301XC10” Standard Tablet |

X

|

|

|

| S-1396 Couple6 Software License |

X

|

|

|

| S-1396- App License |

X

|

BYO App License

i

Includes these 5 basic apps plus Recommended apps : i

Recommended apps i

Choose between this and BYO Apps below:

BYO Apps i

|

Includes these 5 basic apps plus the Professional License apps:

Professional License apps

Optional

|

|

Geometry Apps i

|

Geometry Apps i

|

||

| T-241 Laser/Target USB Charging & Data Communications Cable |

X

|

|

|

| A-810 Rugged Shipping Case |

X

|

|

|

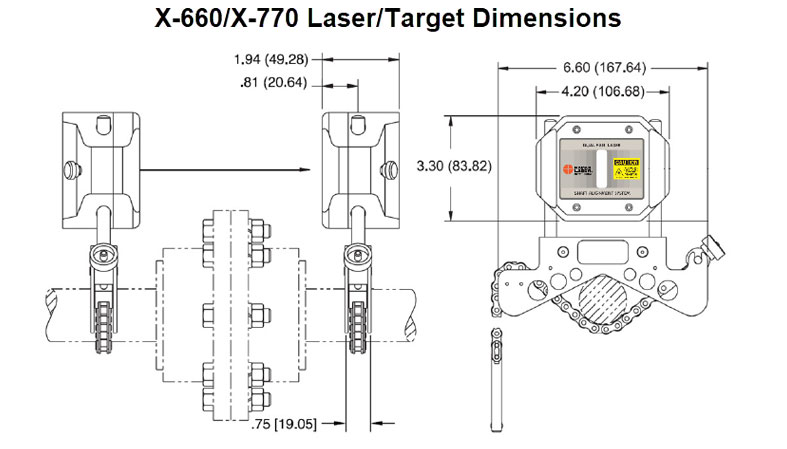

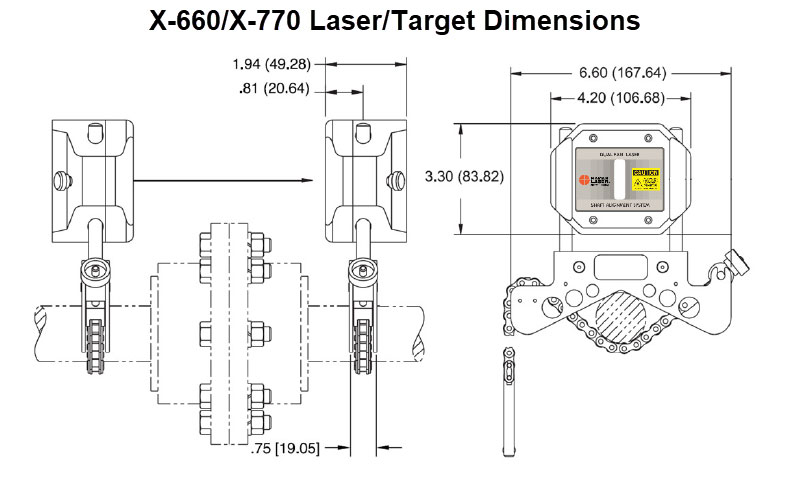

| Laser/Target Unit Size | 4.2 x 3.3 x1.94 in. (107x84x49 mm) |

| Housing Material | Impact resistant plastic |

| Detector Type & Size | 1-axis PSD 20x1 mm provides 2 continuously updating alignment axes (1 alignment plane). |

| Ambient Light Protection | Yes via blinking-laser algorithm embedded in all Hamar targets |

| Target Measurement Resolution | Offset: 1.0 micron (.00004”) Angular: 0.025 mm/m (.0003”/ft.) |

| Target MeasurementError | Offset: <0.75% Angular: <1.5% |

| Angular Sensor Range | ± 8° (± .136 in/in or 13.6 mm/100 mm). For values > 4° use only for rough alignment. |

| Laser Type | 650 nm dual-fan laser with 0.5° fan <0.9mW with 2 mm fan "thickness" to enhance measurement range. |

| Wireless Communication | Bluetooth® Class 2 - 2.4 GHz |

| Wireless Range | Up to 33 feet (10 M) |

| Ruggedized Display Platform | Rugged 10" tablet, IP65, MIL-STD-810G, 2.0 GHz., 8GB RAM/256GB HD. |

| Rotation Sensor (3rd axis) | Accelerometer Resolution: 0.1° Accuracy: ±1°. Measurement accuracy not affected by rotation sensor accuracy. |

| Environmental | IP67 (laser & target). IP65 (R-1342T3-2A or R-1342T-301T). |

| Bracket Set | Covers 1-6 in. (25.4-152.4 mm) shaft diameters. Comes with 6 in. (152.4 mm) posts |

| Application Range | 15 ft. (4.5 m) between laser and target |

| Operating/Storage Temperature | Laser/Target: 5°F to 140°F (-15°C to 60°C) R-1342T3-301XC - AC Mode: -20°C to 45°C (-4°F to 113°F) Battery Mode: 0°C to 45°C (32°F to 113°F) R-1342T3-301XI AC Mode: -20°C to 60°C (-4°F to 140°F) Battery Mode -0°C to 45°C (32°F to 113°F). |

| Battery Life Target | 15 hours continuous use with Bluetooth® — 16 hours with backupcable. Target can be plugged into power source during use. Battery status indicator for both T-1280 Target and tablet. |

| Battery Life Laser | 150+ hours continuous use. Blinking LED indicates low battery status |

| Battery Life Tablets | R-1342T3-301XC - 5 hours(normal use) R-1342T3-301XI – 8 hours (normal use) |

| AC Battery Charger (Laser and Target) | 110V to 220V with U.S. or international adapters. Cable also works as a wireless backup cable and firmware updater. |